Why Coated Abrasives Are Essential for Metalworking in Rosebery

Metalworking professionals face countless challenges when striving for precision, efficiency, and quality in their projects. Without the right tools, achieving consistent results can become an uphill battle. Coated abrasives in Rosebery, NSW, have emerged as a cornerstone of modern metalworking operations, offering unparalleled performance across various applications. If you’re seeking to enhance productivity and deliver flawless finishes, understanding their role is crucial.

Why Coated Abrasives Are So Important:

1. Superior Surface Finishing

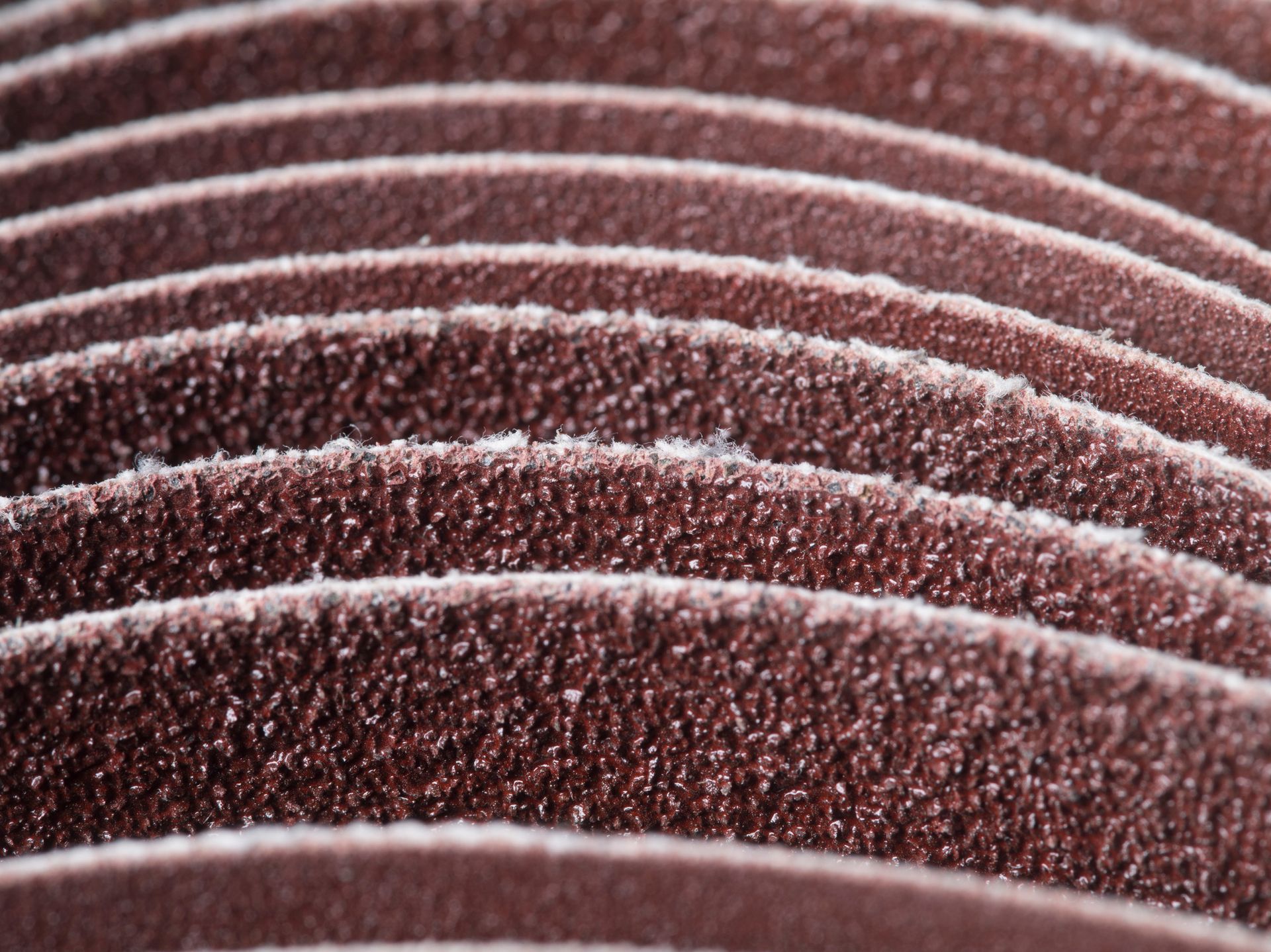

Abrasives are renowned for their ability to produce superior surface finishes on metal components. These tools consist of abrasive grains bonded to a flexible backing, allowing for precise control during grinding, sanding, and polishing tasks. Whether preparing surfaces for coating or achieving a mirror-like polish, these excel in delivering consistent results. Their versatility makes them indispensable in industries ranging from automotive manufacturing to custom metal fabrication.

The fine grit options available in abrasives enable operators to achieve varying levels of smoothness, ensuring that every project meets exacting standards. From coarse grits for heavy material removal to ultra-fine grits for delicate finishing, they provide solutions tailored to specific needs.

2. Enhanced Durability and Longevity

One of the standout features of abrasives is their durability. Engineered to withstand high-pressure applications, these tools maintain their effectiveness over extended periods. This longevity translates into cost savings for metalworking businesses, as fewer replacements are required.

Coated abrasives in Rosebery, NSW, are designed with multi-layered bonding systems that prevent premature wear, ensuring consistent performance throughout their lifespan. This reliability makes them a preferred choice for demanding industrial environments where downtime must be minimised.

3. Versatility Across Applications

From deburring and shaping to finishing and polishing, abrasives offer unmatched versatility. They can be used with various tools, including belt sanders, disc grinders, and orbital sanders, making them adaptable to different workflows. This adaptability ensures that metalworkers can rely on them for a wide array of tasks without compromising on quality or efficiency.

Here are some common applications where these abarasives shine:

· Deburring: Removing sharp edges and excess material after cutting or machining.

· Surface Preparation: Cleaning and smoothing surfaces before painting or coating.

· Polishing: Achieving high-gloss finishes on stainless steel and other metals.

· Grinding: Removing weld seams or imperfections from metal surfaces.

· Shaping: Creating custom designs and contours in metal components.

4. Improved Safety and Operator Comfort

Safety is paramount in any metalworking operation. Abrasives contribute to a safer working environment by reducing the risk of tool malfunction and minimising dust generation. Furthermore, their ergonomic design reduces operator fatigue, enabling longer, more productive work sessions. Operators benefit from reduced vibration and noise levels when using coated abrasives, which enhances overall job satisfaction and reduces the likelihood of repetitive strain injuries.

5. Cost-Effectiveness Without Compromise

Investing in high-quality abrasives is a cost-effective decision for metalworking businesses. Their efficiency reduces labour time, while their durability minimises material waste. When combined with their ability to deliver exceptional results, these prove to be a smart financial choice.

For instance, the use of abrasives can significantly cut down on rework due to poor surface finishes, saving both time and resources. Additionally, their long lifespan means fewer interruptions for tool changes, leading to smoother production cycles.

Choose Our Solutions of Coated Abrasives

For expert advice and access to premium coated abrasives, call L.D. Beston at (02) 9662 6222. As leaders in coated abrasives in Rosebery, NSW, we are committed to supporting your metalworking needs with industry-leading products and services.